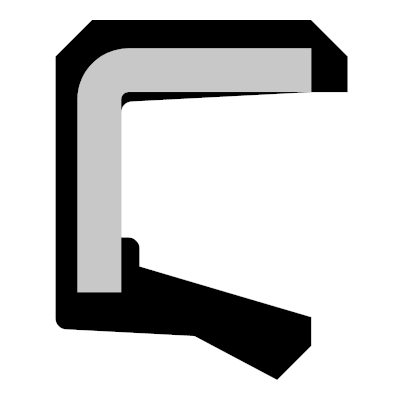

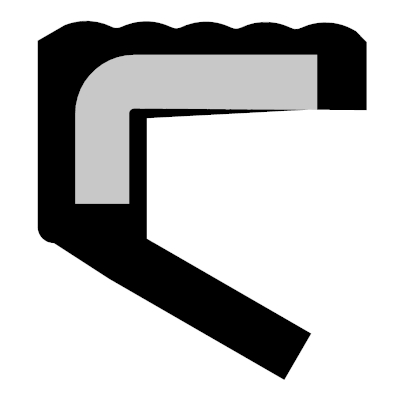

Rubber Covered O.D.

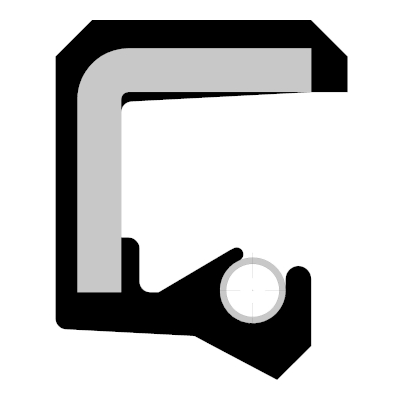

The area between the sealing edge and the shaft is the most important. The sealing effect is achieved by preloading the sealing lip, making its internal diameter slightly smaller than the shaft diameter.

The garter spring ensures constant mechanical pressure and maintains the radial force to the shaft, flattening the sealing edge to a defined width. Sealing is provided by the surface tension of the hydrodynamic oil film between the seal flattened area and the shaft.

The meniscus acts as an interface between the outside air and the fluid. Any break in the meniscus will result in leakage. This can occur if the shaft contains scratches along the seal path.

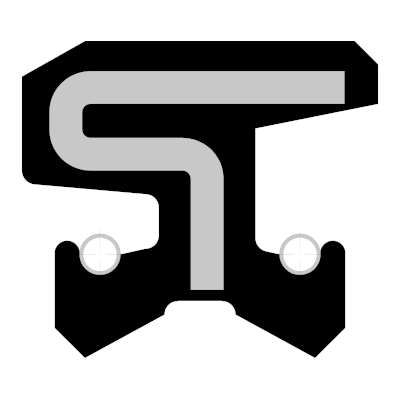

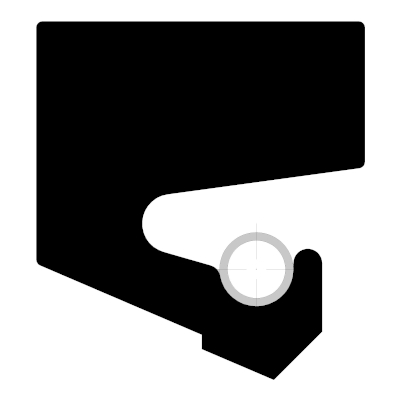

AS-PX

Reinforced sealing lip and special metal insert for overpressure, with additional dust lip.

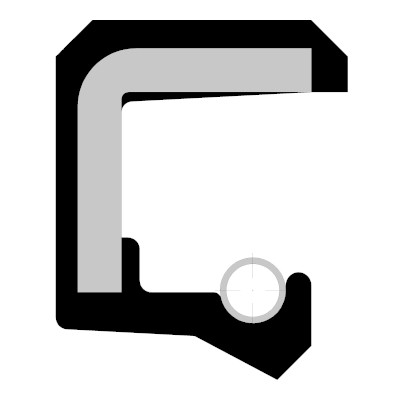

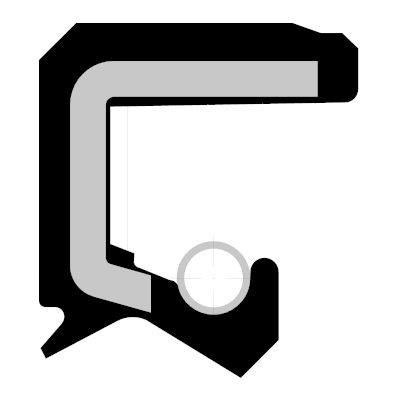

ASX7

Waved rubber covered O.D., metal insert, sealing lip with garter spring, with or without dust lip.

DINA SEAL WAVED OD

Rotary shaft seal for needle bearing applications, without spring.

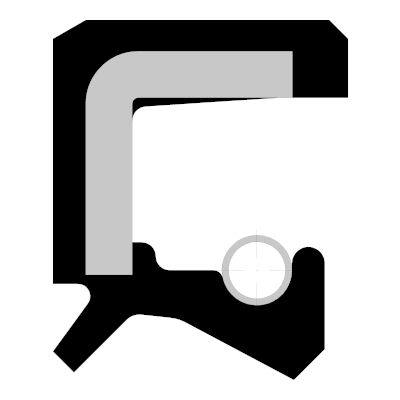

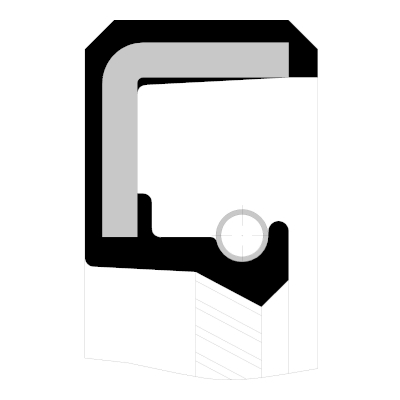

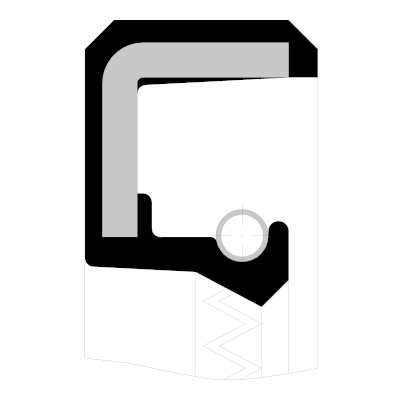

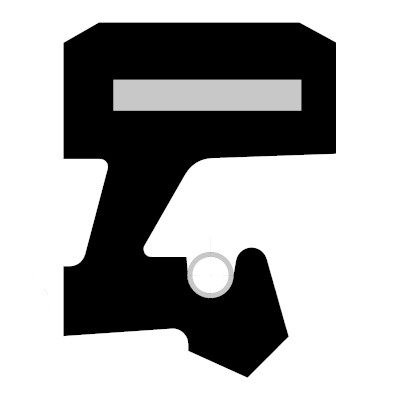

AX-7M

This seal is designed for use in presence of pressure, up to max 0.6 [MPa]. A metallic band is inserted in the back of the seal. It is assembled in open housings and does not need a retaining flange. This profile is flexible and easy to assemble, ensuring stability in the housing.

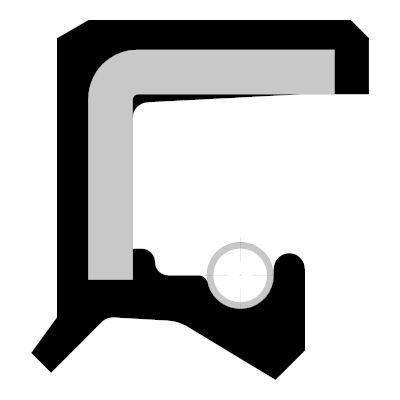

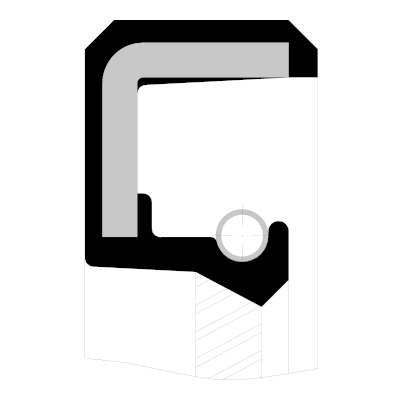

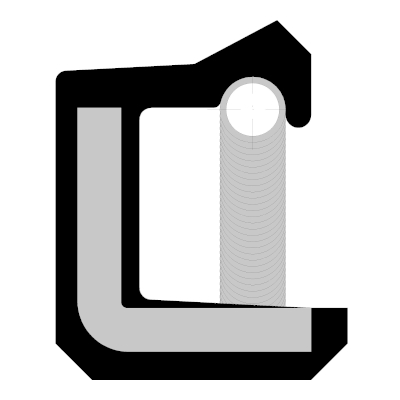

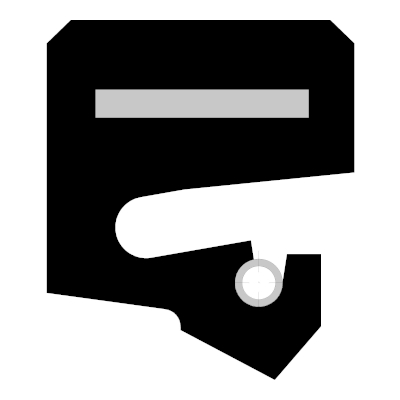

AX-3M

This seal does not need the retaining flange. The rubber seal has a flexible metal band in its shoulder, which makes it resistant, elastic and easy to install. This seal can be assembled in open housings and has a better resistance to possible misalignments. The spring is more protected than in standard seals.

AX-3ML

Same profile as the AX-3M, but with a rigid metal insert inside the shoulder, instead of the flexible metal band.