Rod & Piston Seals

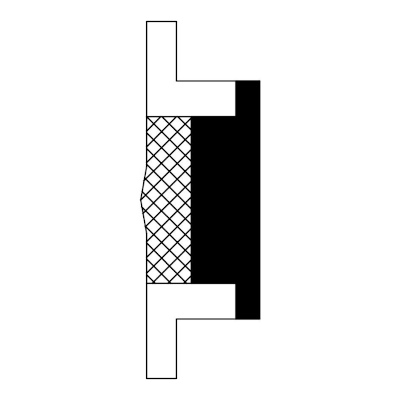

Rod and buffer seals maintain sealing contact in sliding motion between the cylinder head and the piston rod. The goal is to prevent the escape of the pressurized operating medium from the cylinder and the contact with external contaminants.

Depending on each application, a rod sealing system can consist of a rod seal and a buffer seal or a rod seal only. DICHTA® offers the right profile for a wide range of cylinders and applications.

Rod sealing systems for heavy duty applications typically consist of a combination of both seal types, whereas the buffer seal is placed between the rod seal and the piston in the cylinder head.

Rod seals determine the tolerance for the rod diameter. Beyond their sealing function, rod seals also provide a thin lubrication film on the piston rod that lubricates themselves and the wiper seals. The lubricant also avoids corrosion of the piston rod surface. On the other hand, piston seals keep sealing contact between a piston and cylinder bore.

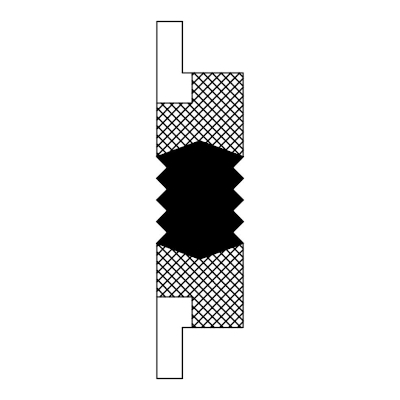

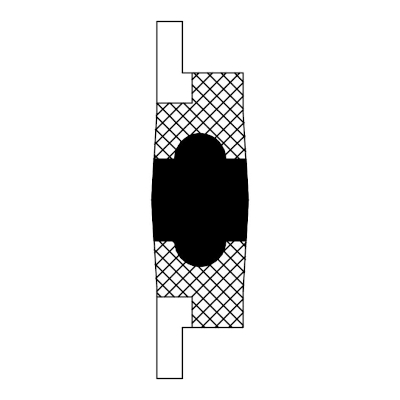

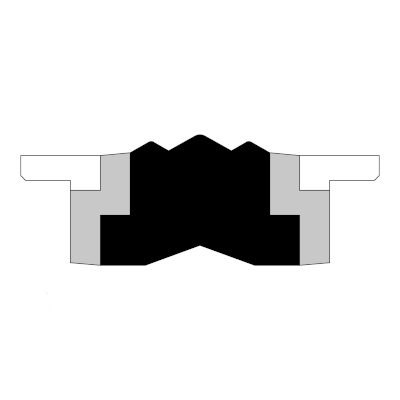

The moving piston rod makes high pressure on the piston seal which enhances contact forces between the seal and cylinder surface. Piston seals are regularly classified into single-acting (pressure acting on one side only) and double-acting (pressure acting on both sides) seals.

ROD

PISTON

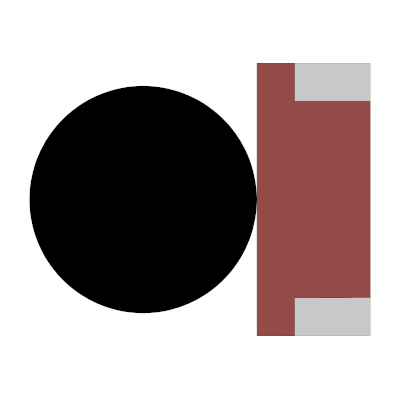

DEP

Double-acting piston seal with sealing ring in NBR, anti-extrusion rings in thermoplastic polyester resin and guide rings in POM reinforced with glass fiber.