Mechanical Face Seals

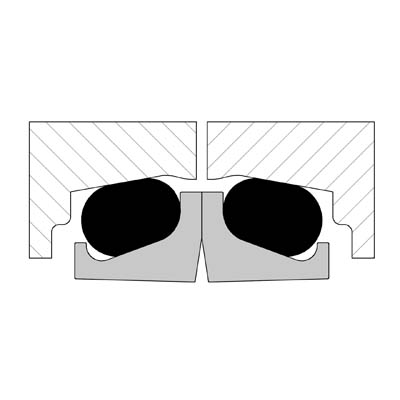

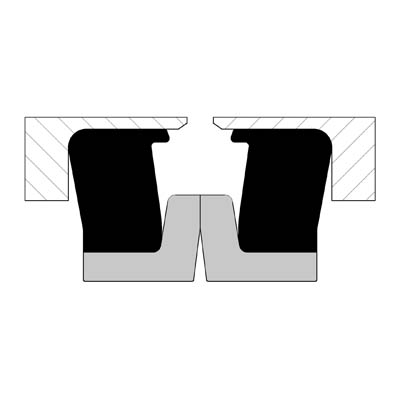

Mechanical Face Seals consist of two metal seals and two elastomeric components, which are mounted into two separate housings.

The elastomeric parts, as a secondary seal, take over the function of the elastic force of the spring, the static sealing between the sliding ring and the housing as well as the torque transmission.

The perfectly lapped contact surfaces of both metal sealing rings are pressed and axially slide on each other.

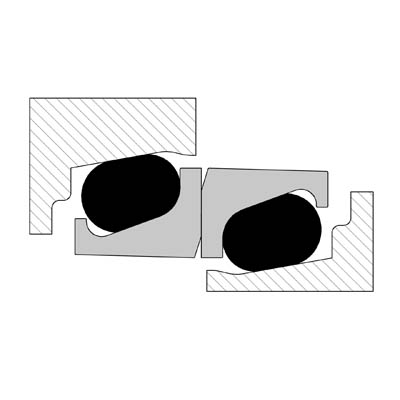

An essential functional feature of the Mechanical Face Seal is a robust construction form combined with very long lifecycles.

The selection of the most suitable materials for the sliding ring and elastomeric part ensure high wear resistance. Mechanical Face Seals guarantee a fully adequate corrosion protection, as well as optimal lubricant and temperature resistance.

O-rings’ materials assure minimal power loss over the life of the drive seal. Thus, this seal typology is technically superior to other types of construction.

Mechanical Face Seals are especially used for rotary shafts in severe and dirty environments. Due to their outstanding technical features Mechanical Face Seals have achieved worldwide distribution.

Available in steel or cast iron, DICHTA® will provide you with further information upon your inquiry.