Frontseals®

Frontseals® is a registered trademark of Dichta SA used to identify our own production of V-rings.

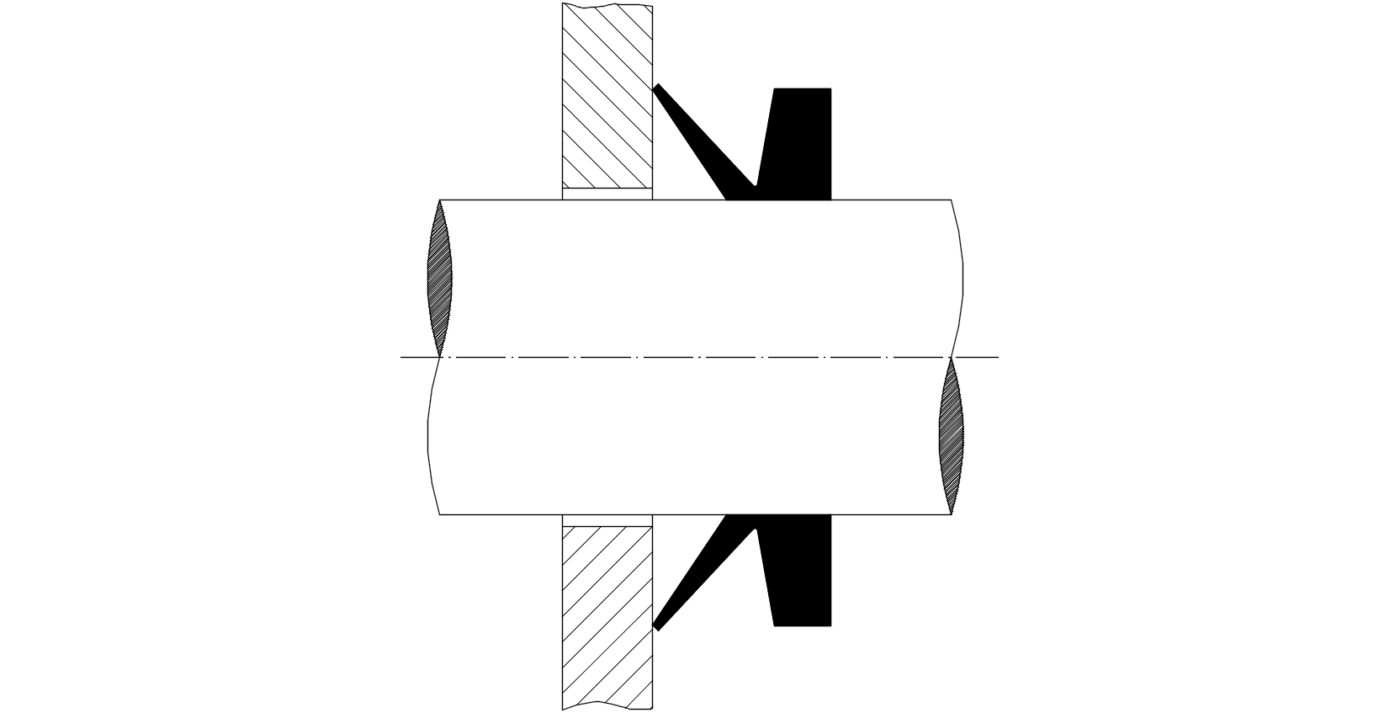

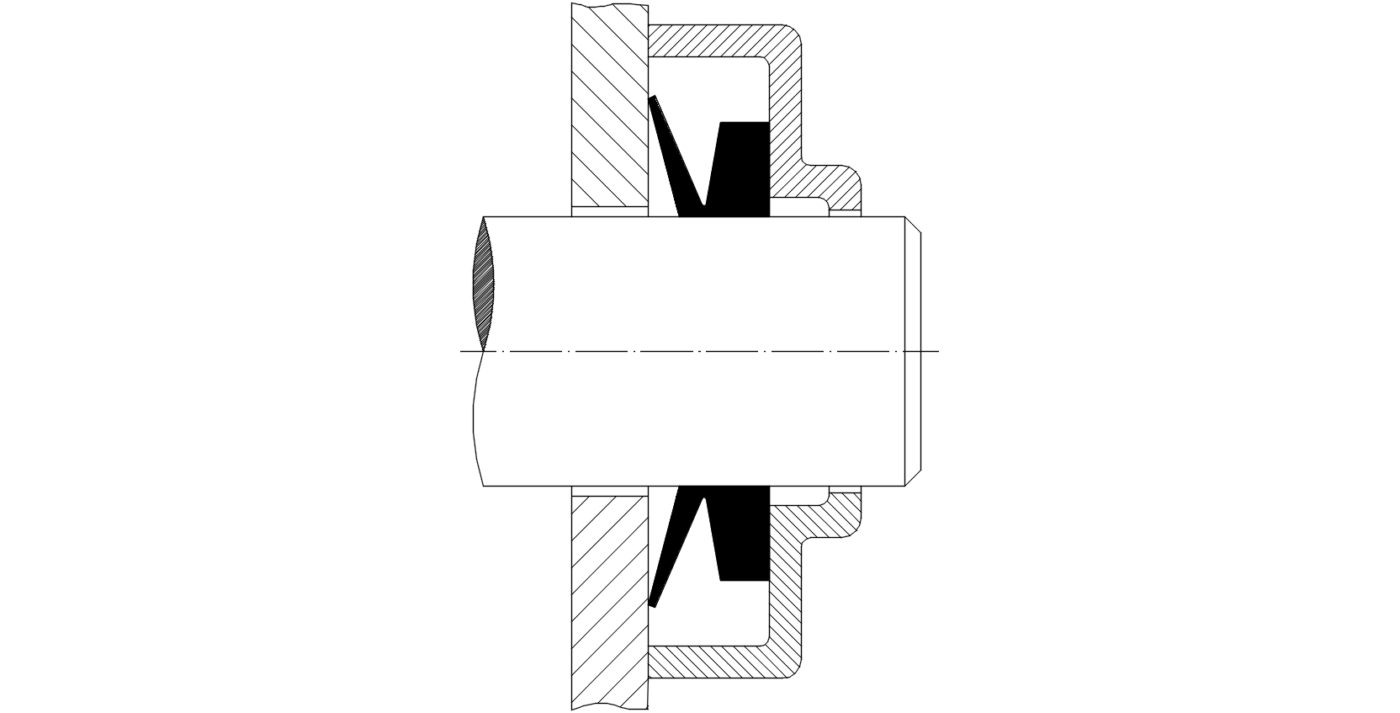

The Frontseal® is an all elastomer axial seal for rotary shafts and bearings. It rotates with the shaft and seals axially against a stationary counterface perpendicular to the shaft.

This type of seal has been used widely for several applications and has proved to be reliable and effective against dust, dirt, water and oil splash and other media.

Thanks to hot-vulcanization process the dimensional possibilities are unlimited.

Fitting

Fitting a Frontseal® is very simple. The ring must be slightly stretched and pushed along the shaft. It can either be done manually or with a simple tool, in a way that the distance to the counterface can be maintained constant over the circumference using little pressure.

The lip of the Frontsea® should be lubricated with a thin film of grease or silicone oil. In case where frictio must be reduced, coat the counterface with a low friction agent and do not apply grease to the lip.

The shaft should be preferably dry and free from oil and grease.

Frontseal®fitted with preloading using a tool

VA*

It’s the most common profile. It has a perpendicular rear face. Wide range of sizes, from 3 to over 2000 [mm] shafts.

VS

Wide body to ensure higher radial force than VA type. Range of sizes from 5 to 199 [mm] shafts.

VL

This seal is intended for applications where available space is narrow. Range of sizes from 110 to over 1200 [mm] shafts.

VAX

Heavy-duty Frontseal® , primarily designed for large high speed bearing arrangements, used for instance in rolling mills and papermaking machine applications. Additionally it can be used as secondary seal for heavy-duty applications where the primary seal has to be protected against water and/or particular contamination. Range of sizes from 200 to over 2000 [mm] shafts.

VE*

It’s a heavy-duty large diameter seal, used for instance in steel milIs, paper milIs and rolling milIs as a dirt/water excluder seal. A clamping band can be used to improve axial fixation. Range of sizes from 300 to over 2000 [mm] shafts.

VRME

This heavy-duty profile is also primarily designed for protecting high speed bearing arrangements in rolling mills, papermaking and large machine applications. A clamping band can be used to improve axial fixation. Non-standard profile, production on demand.